China on track for ultra-high speed trains with hyperloop test ‘setting record’

- According to CASIC, its high-speed flier surpassed previous records using full-scale test line to travel 2km with stable levitation

- The result is a ‘significant breakthrough’ for the project, which is aiming for speeds of up to 1,000km per hour

While the exact speed reached remains classified, the Third Academy of China Aerospace Science and Industry Corporation (CASIC) said it had made “a significant breakthrough” with its latest test.

According to CASIC, it was the first time the maglev achieved stable levitation while travelling in a low-vacuum tube, using the full-scale 2km (1.2-mile) test line that was completed in November.

CASIC said the results surpassed the previous known record set by a superconducting maglev vehicle – 623km/hr (387mph) under non-vacuum conditions, as reported in October 2023.

A month earlier, a similar test of high-temperature superconducting maglev technology achieved 234km/hr (145mph) on a 380 metre (1,250ft) track.

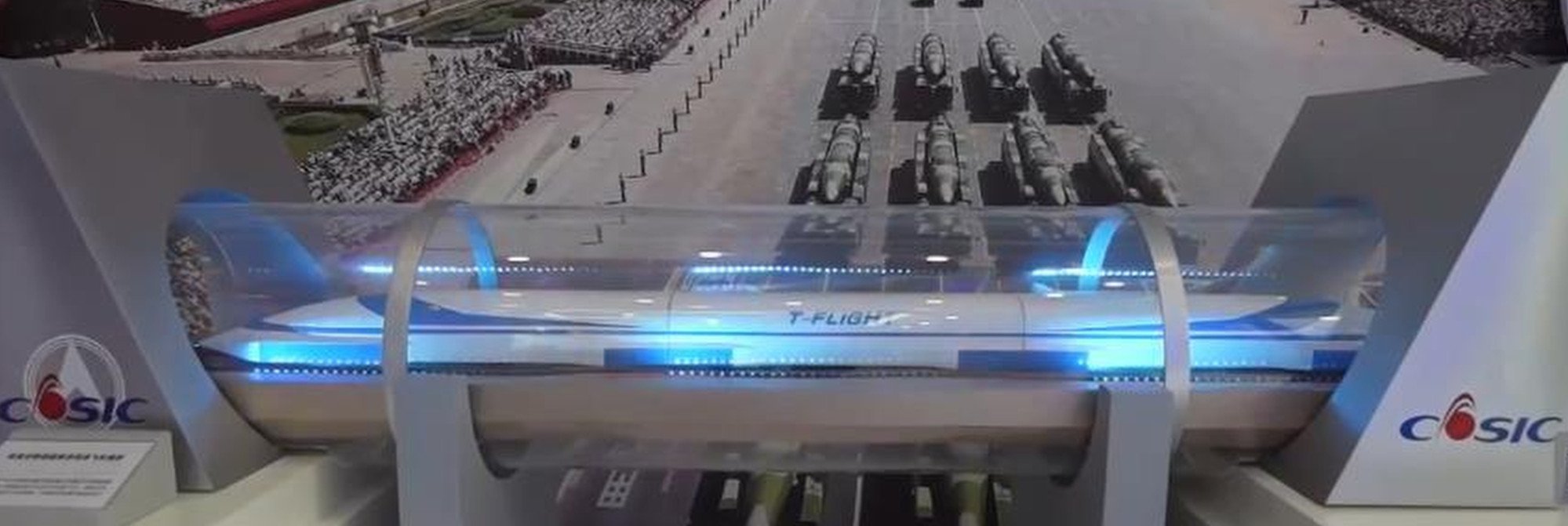

China has a new test system for maglev trains that ‘fly on the ground’

The high-speed flier project integrates aerospace and terrestrial rail transport technologies, with a designed speed of up to 1,000km/hr – surpassing commercial aviation speeds.

The superconducting maglev technology “levitates” the train to eliminate friction as it travels through the specially designed low-vacuum tube. The near-vacuum conditions reduce air resistance, achieving “near-ground flight” at ultra-high speeds.

According to CASIC, the test not only set a speed record for the system, it also validated several key technologies and proved that they work well together.

The test line, in Datong, Shanxi province, northern China, is the longest and biggest of its kind and represents China’s first full-scale testing facility for an ultra-high-speed low-vacuum tube maglev transport system.

Construction officially began in April 2022, led by CASIC’s magnetic levitation and electromagnetic propulsion technology department, which was established in January 2018.

Accuracy was critical – with millimetre-level precision required for the concrete surfaces supporting the equipment. Variation in the flatness of the track could not exceed 0.3mm, according to CASIC’s website.

Several integrations and safety checks are also necessary when the train transitions from levitation to motion, highlighting the significance of the test line’s first phase completion.

The main body of the first phase features a platform with an upper and lower structure in an “n” and “u” shape, respectively. This supports “nu” shaped tubular beams, each nearly 6 metres (20ft) in diameter and 21 metres (69ft) long.

The tubes have a geometric size error of less than 2 millimetres (0.1 inch) and must be capable of maintaining a vacuum state for extended periods, presenting significant challenges in fabrication and installation.

With no domestic precedents for the high-speed flier, many construction details could not be fully represented in drawings, CASIC said. Instead, they had to be summarised and confirmed through practice before being validated in the engineering project.

Breakthrough in China hyperloop project aiming to transport people at 1,000km/h

“Science and technology progress step by step, and some aspects of this project are still in uncharted territory in China. Every step is challenging, and it’s a complex system,” said the project’s chief designer Mao Kai, in an interview with Zhejiang Daily.

According to official reports, the test proved that the vehicle tube and track interact well, keeping the heavy maglev vehicles floating steadily. The powerful movement systems and overall safety controls also functioned as expected.

These advances had improved the overall technical maturity of the system, laying a solid technical foundation for future higher-speed tests and the construction of a national level transport network, CASIC said.

According to the China National Space Administration, the same CASIC department is also working on the country’s next generation commercial aerospace electromagnetic launch systems.